UCH-V2 TECH SPECS

UNICHANNEL MODULAR IN-CEILING SHADE CONCEALMENT SYSTEM

UniChannel is a modular system that conceals window shades inside a ceiling.

UniChannel is supplied as a pre-made MDF carcass with plaster-in flanges, a removable bottom trim cover, and an easy-to-use 'Twist-In' shade bracket mounting system that is compatible with Future Automation shades. The MDF carcass can be easily cut to size on site and is supplied with aluminium side channels and locking friction fixings pre-installed to make assembly simple.

The Unichannel system also features a hook-on cover panel that has been designed to attach at two different depths. The lower position sits flush with the ceiling and allows for easy access to the shades and can be painted to match the surrounding ceiling. In the higher position you can attach a fascia cover panel that can be finished to match the surrounding ceiling for a seamless transition between the UniChannel system and the surrounding ceiling.

Typically, installing shades inside a ceiling involves constructing an MDF or plywood carcass above the window, and then fitting an expensive aluminium channel into this carcass to mount the shades. UniChannel eliminates the need for this costly aluminium channel by integrating it directly into the MDF carcass that contractors would already be building in the ceiling void. This lower-cost alternative simplifies the process of installing window shades inside a ceiling.

INNOVATIVE

SIMPLICITY

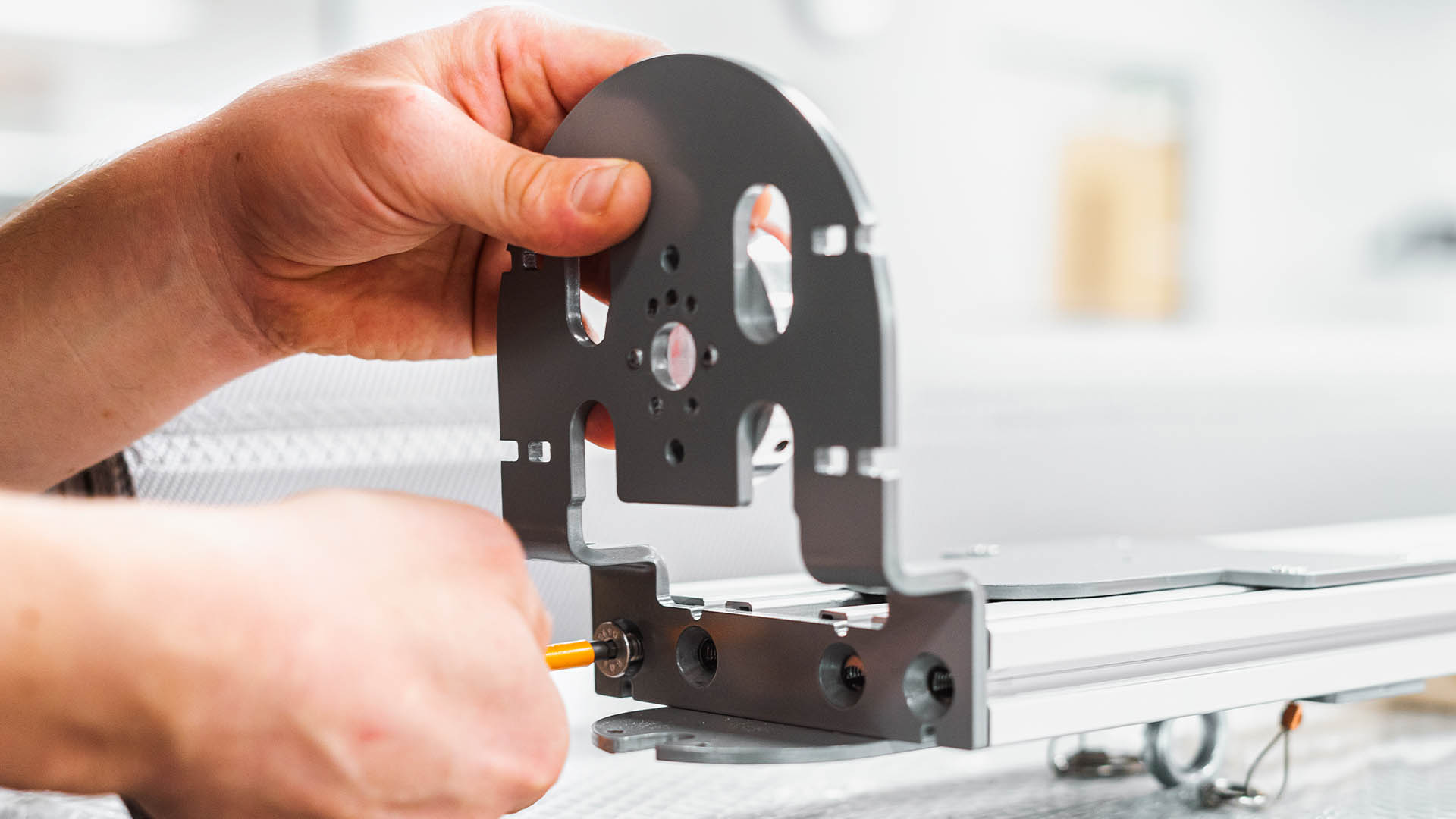

The innovative ‘Twist-In’ shade bracket mounting profile inside the UniChannel means that Future Automation shade fixing brackets can be inserted and locked into place inside the pocket (before being finally secured via mechanical fixings). This prevents fitters from having to juggle shade brackets and tools above their heads during shade installation. Shades from other manufacturers can be mounted inside the UniChannel system, but they won’t benefit from the easy ‘Twist-In’ bracket mounting system.

To allow for a clean ceiling finish, the UniChannel system is supplied with two plasterboard fixing flanges, as well as an aluminium bottom flap. The plasterboard fixing flanges allow the system to be boarded and skimmed into the ceiling after fitting, to create an almost seamless join between the pocket and the finished ceiling. The removable bottom flap has two fixing positions, enabling it to either be visible and sit flush with the finished ceiling (powder coating available on request) or be raised up and have an MDF panel applied which can be hand-painted on-site to match the ceiling finish colour.

HAND CRAFTED IN HOUSE